Solving Intermittency Today

for Smarter Energy Storage Tomorrow

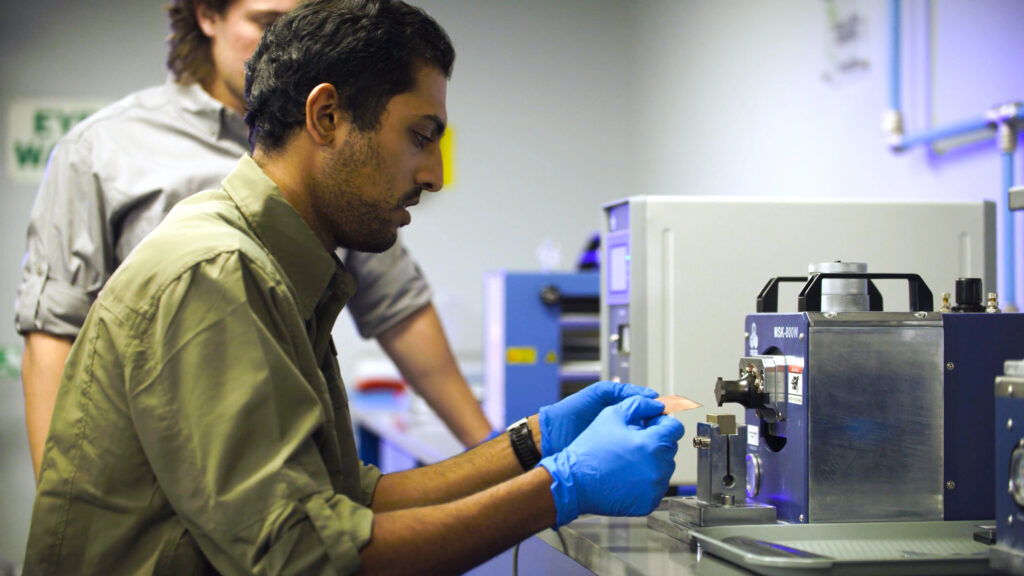

Dragonfly Energy has set out to develop cleaner and less wasteful processes to create lithium-ion batteries. Our cutting-edge technology is enabling the widespread conversion to green, renewable energy. We produce batteries that solve today’s lead-acid problem and are creating next-generation nonflammable solid state batteries to address tomorrow’s energy storage needs.

Our Technology

Dragonfly has set out to develop cleaner and less wasteful processes to create lithium-ion batteries.

Conventional Li-ion Cell Production

Producing lithium-ion battery cells is a messy and expensive process. Nasty solvents are required for dissolving the polymer binder during electrode coating. These solvents must be removed and reclaimed prior to cell assembly using power-hungry ovens and vacuum systems. It is a time-consuming process that ultimately drives up the cost of energy storage.

A Focus on Storage Batteries

With the race to find the perfect battery for EV applications, the industry has neglected the much more critical need for storage solutions. The more EV’s that are brought to market that charge daily from the grid, combined with increased technology in today’s culture, the more increased power demands begin to stress an already antiquated power grid. Here at Dragonfly Energy, we’ve identified this need to support the grid by enabling more renewable energy resources. And due to the intermittency of those resources, this means storage.

LiFePO4 has already proven to be the perfect battery chemistry when looking at storage purposes. It has a long lifespan (3,000+ Cycles), low levelized cost and is safe. So our focus is not the cell chemistry, but rather the manufacturing process. We have developed a dry, solvent-free process whereby electrodes are rapidly grown one particle at a time. We can produce conventional cathodes and anodes with no solvents, no ovens, and no vacuum.

We produce double-coated anodes and cathodes, composed of any chemistry, with a fraction of the binder, in a reel-to-reel fashion. Powder in, cell out. It’s that simple. And cycling behavior is not compromised.

Clean American Manufacturing

What this means, is a significantly reduced manufacturing footprint, allowing for rapid scaling of production at reduced costs. All done domestically to ensure a reliable supply chain while bringing important jobs to Americans.

This positions Dragonfly Energy uniquely in the industry, as once cell production begins, we’ll control the entire process. From design, manufacturing and assembly of battery products to integration of full power systems backed with the exemplary technical support and services our customers have come to expect.

Non-Flammable Solid State Battery Cells

These proprietary solid state battery cells contain a solid electrolyte, instead of a liquid electrolyte, thus removing the flammability of the technology. Combined with our patented manufacturing process, these cells still maintain the high performance and longevity LiFePO4 battery chemistry is known for.

We have validated our non-flammable solid state technology and are currently optimizing the cells and preparing for production. Our unique solid-state technology is purpose-designed for cost-effective, highly scalable manufacturing. Our patented process allows us to rapidly grow the electrodes, interfaces, and solid electrolyte layers one particle at a time. With no solvents, no ovens, and no vacuum. Just instant cell production.

Distributed Storage & Smart Grids vs. Centralized Storage

A centralized grid system is what we’ve most commonly seen in our country for electrical power management and is typically located where the resources are most available. These require large capital investments and have power generated from fossil fuel power plants, nuclear power plants, hydroelectric dams, wind farms and more.

Whereas Distributed Storage is a power solution that stores the energy generated for use at a later time. When connected to the electric utility’s lower voltage distribution lines, distributed generation can help support delivery of clean, reliable power to additional customers and reduce electricity losses along transmission and distribution lines. Smart Grids and Microgrids allow energy generation and storage from buildings and houses all over the country, harnessing renewable energy and feeding it between the consumer and the grid as demands require.

Through this, batteries remain the most scalable type of grid scale storage available. And since these unique manufacturing processes we’ve developed enable us to create a battery that is safe with 100% non-flammability and long lasting with projected 5,000+ cycles life, this opens the door to widespread distributed storage deployment as a tool to help reduce stress to the country’s power grid.

We believe that we have found a way to drop the price of energy storage globally. While this is one step in the right direction, we imagine a future where Dragonfly’s smart storage solution will allow for less reliance on the power grid with ample access to back up power by distributing energy.

Find our latest updates on our press page.

View our product patents here.